MTS explore one of the critically important aspects of any mining technology and asset health program – the importance of data quality.

Four Tips for Identifying Bad Asset Health Data in the Mining Industry

The initial idea for this MTS blog came in March whilst we were at the airport (remember those?) waiting to fly to South Africa. One area that we’ve noticed getting a lot more focus over the past year is mining industry analytics for asset health monitoring. We’ve been passionate about this aspect of mining technology since we started, so we think this is really exciting!

We have previously blogged about Tips for Establishing a Successful Asset Health Programme in the Mining Industry, but in light of the renewed interest, we’re now going to explore one of the critical parts of any asset performance management program – the importance of data quality.

Ignore “Dodgy” Data at Your Peril

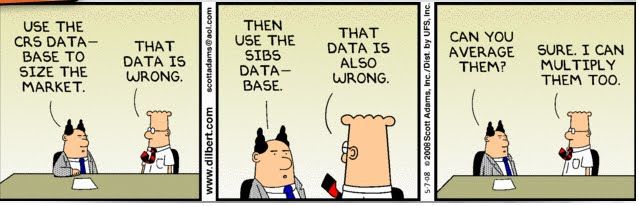

It’s fantastic that big data analytics in the mining industry is moving in the right direction. Our concern is that while everybody is distracted by shiny new graphs and pie charts, not enough attention is being paid to what is “under the hood” of asset performance software – the quality of the data itself (as generated by the equipment) and the possible downstream impact of poor data quality on any attempt at mining data analytics.

Our Top Four Tips to Monitor Asset Condition in Mining

Before you begin to implicitly trust your raw asset health management data, it’s wise to perform some simple validation checks.

1. Ask to see the “raw” data.

This should be the first step. Looking at aggregated data in a pie chart (we’re surprised at how often these are used) will not provide you with the correct grain of detail to perform a basic validation. It will mask common issues such as duplicate events or power-cycling tests causing false alarms. These can easily be picked up by looking at an Excel dump.

2. Sanity check the numbers

Once you have the numbers, sit down with SMEs to review them:

- Do these voltages look correct for that wheel motor?

- Does that brake differential temperature look sensible?

- Is the number of alarms in this time period reasonable?

3. Are you getting all of the expected parameters?

This is regularly missed, but checking if all possible parameters are coming through from your mining technology is vital because the extra data can pay dividends in any asset condition monitoring.

- Speak to the OEM and ask them what data is available over their J1939/CAN connections.

- Then compare this with what you’re actually getting (we regularly find instances where there are large discrepancies).

Typically resolution involves upgrading the hardware or firmware on the machine (warning: this can be painful, particularly if this is something completely new to your local support rep who may be more used to helping out with the iron – but it’s worth the effort!).

4. Compare with other data sources

Finally, try to cross-compare with a similar condition monitoring solution. For example, if the OEM has cloud-based asset performance software then compare the numbers between the two systems. This isn’t always possible but it’s a great way of doing a final (if crude) validation.

We hope this helps. Harnessing asset health data is a fantastic opportunity for mines to continue their drive to reduce operating costs through mining data analytics using their mining technology. Applying these four simple steps will help this journey just go a little more smoothly.

Asset Performance Software: Trend Exceptions Tool

Once you have stable, clean, integrated data from your condition monitoring solutions, it is possible to perform mining data analytics using a range of different data types. One example is our Trend Exceptions Tool (shown below).

Trend Exceptions Tool displays asset health alarms and data trends over a range of time periods and allows asset health analysts to see if and when a machine is trending outside of OEM or custom specifications.

Are you still experiencing problems with your asset performance management data?

Find out more about how we can help with your mining technology, asset health condition monitoring, and mining industry analytics by getting in touch at info@minetechservices.com

[DISPLAY_ULTIMATE_SOCIAL_ICONS]

Write a Comment