5 ways AI is helping miners improve safety and reduce environmental impact

Mining has long been linked to negative environmental impacts and safety concerns. However, the industry has seen a significant shift in recent years (although there are still some frustrating regional outliers). More recently, technological advances in artificial intelligence (AI), sophisticated machine learning algorithms, and advanced analytics are helping the industry become even safer and more sustainable.

By gathering and analysing large amounts of data quickly and effectively, AI can help reduce the impact of mining operations on the environment. Drones and autonomous vehicles driven by AI are now capable of carrying out risky operations that formerly required workers to be present in remote locations. With the use of real-time data, analytics and predictive maintenance solutions, mines are able to prevent accidents, reduce environmental impact, boost efficiency and output, while lowering operational costs.

In this blog, we explore 5 ways in which AI is being used in the mining industry, the benefits it offers, and potential implications for mining’s future.

1. Safety

The mining industry has made great strides in increasing the health and safety standards of its operations, and the industry is arguably the safest it has ever been. This transformation is being furthered by the use of AI, which is able to predict failures and reduce accidents.

AI-powered tools like wearable sensors are able to continuously monitor worker behaviour to detect any sign of physical discomfort, driver drowsiness or fatigue. For example, in its Chilean copper mine, BHP implemented the use of SmartCaps, which analyse the brainwaves of the drivers, alerting them as soon as it detected drowsiness.

Real-time monitoring and data analysis using machine learning is another less obvious (but no less impactful) use of AI. By detecting failure symptoms, machine learning can help predict and eliminate catastrophic failures, which not only help reduce the cost of repair, but also eliminates any risk to the operator.

2. Autonomous vehicles

One of the most significant applications of AI in mining is through the use of autonomous vehicles, which can operate without human intervention in hazardous and remote environments.

AI-powered trucks can traverse challenging terrain and detect obstacles, reducing the risk of accidents and improving safety. Autonomous vehicles are being deployed in mines around the world, carrying out activities such as drilling, blasting, hauling and loading parts of the mineral extraction and transportation process. This increases productivity while eliminating risk and removing people from potentially dangerous situations.

An example of this is being able to run mining equipment through shift changes or blasting activities. This is especially valuable in underground mines or operations where there is lengthy downtime due to operators having to travel to the machine they will be working on.

Mines that do not adopt this technology will soon find it hard to compete with the reduced cost and increased productivity of mines that leverage the advantages of AI.

For example, drones are increasingly being used to conduct site surveillance, inspect equipment and blast sites. Data collected from these drones can be used along with advances in AI, image processing and photogrammetry to monitor slope stability and survey dangerous locations without putting operators at risk.

3. Efficiency of mining exploration

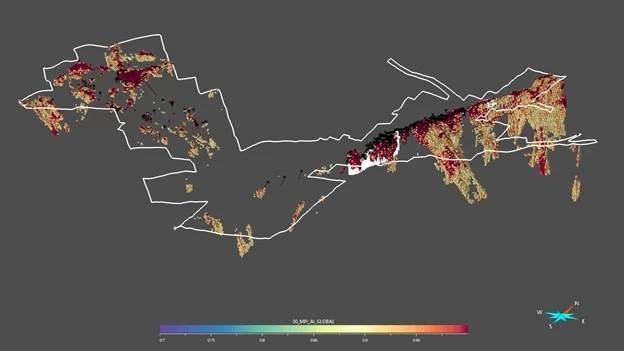

Besides autonomous vehicles, AI and machine learning are also being used to enhance the accuracy and efficiency of mineral exploration. MTS’s partners at SRK consulting recently showcased such an approach. AI algorithms, for instance, can quickly analyse geospatial data to pinpoint the most likely locations of mineral deposits and other resources. This, combined with other disruptive technologies in the industry, including the use of drones to replace costly and time-consuming fieldwork will greatly speed up the entire exploration process.

Another massive application for AI in exploration/mining is in the Image Processing space. The development of ML imaging software can allow the instant identification of different lithologies in images of drill core, face and pit wall photos. This drastically improves the time for information that is critical for mine planning can be gathered and utilised.

A noticeable example of the use of AI in exploration is KoBold Minerals (More info here). This company, focused on prospecting for critical battery metals, has developed extensively into the AI space, allowing them to build advanced predictive models that utilises satellite data combined with more traditional datasets, to identify potential mineral targets. Currently they are exploring over 60 projects around the globe and have entered into numerous JV partnerships with established miners to develop some of these projects further. (e.g. Bluejay in Greenland)

Check out this case study of how AI has been used to generate exploration models for Revival Gold in Idaho USA from Mira Geoscience.

4. Predictive maintenance

The mobile mining sector is also leveraging AI and ML to enhance maintenance and repair. Machine learning algorithms can be used by predictive maintenance systems to assess sensor data from machinery and predict when maintenance is required, thus reducing downtime and increasing productivity. (More info here.)

Additionally, these algorithms can examine data to find patterns and identify root cause of equipment failure, thereby predicting and preventing upcoming failures. With the help of these technologies, mines can make better judgments, lower the risk of accidents, and streamline operations.

5. Reduced environmental impact

Mining by its very nature, is a destructive process often associated with the formation of sinkholes, erosion, loss of biodiversity and soil contamination. The introduction of AI, however, is dramatically reducing mining’s negative impact on nature.

For example, sensors and cameras deployed in mines around the world are able to monitor excavation and extraction activities. By detecting anomalies such as temperature changes and tremors, or chemical leaks, these sensors are able to avoid accidents and environmental disasters.

Moreover, data from sensors and cameras can be analysed to help reduce waste and lower the power consumption of the mining industry. For example, AI-based automatic regulation of ventilation systems is a key factor in saving power.

Monitoring tailings dams is another powerful application of AI in the environmental space. By combining and analysing data from various sensors. Real time, continuous monitoring can be carried out ensuring any potential weaknesses in the dam can be addressed promptly before failure.

With mines across the globe becoming more and more environmentally conscious, the adoption of AI has the potential to greatly contribute towards sustainable mining practices.

What does the future of mining look like?

As the adoption of AI and ML continues to grow in mining, it’s likely that we’ll see even more innovative applications of these technologies in the future.

As technology evolves, AI-powered mining equipment and sensors are expected to become more sophisticated, with higher accuracy and better predictive capabilities. For instance, AI-powered virtual reality technologies could be used to simulate mining scenarios and test new technologies before they are deployed on-site. With the advent of 5G networks, AI-powered devices, and systems are likely to be even more connected, allowing for real-time data analysis and faster decision-making.

In the mineral exploration space it is well known that only about 1 in every 1,000 projects is successful. AI provides a massive opportunity to increase this success rate and the speed at which new projects come on stream, going a long way to securing critical resource supplies for the future.

With a growing consciousness among mining companies to become more sustainable, more ethical and more efficient, the future of AI in mining looks promising.

Security Risks and Skills Gaps

While the use of AI in mining offers many benefits, the industry must also consider concerns surrounding AI, like potential job loss and data security. Mines must also have strong data protection practices in place. On the other hand, recruitment within the mining industry is becoming a major challenge and this move towards more autonomous/AI driven operations will provide a solution for mines struggling with recruitment.

It is worth noting that the transition to AI will require different skill sets and expertise than are traditionally present in the industry. While there is a healthy appetite for modernising skill sets and embracing new technology within the existing workforce, the industry needs to start thinking about how they will attract the necessary talent for years to come.

The Bottom Line

It is evident that AI has now arrived and is quickly becoming a part of common mining practices. While it will bring challenges in terms of skill sets, jobs, and cybersecurity, MTS is confident that the industry will adapt; and most importantly, everyone will reap the benefits of improved safety, reduced emissions, and increased productivity that AI can bring.