What metals are used in the production of green technologies, and why the mining industry needs to adapt and extract them responsibly…

In recent times, mining has undergone a profound shift in focus. While it once revolved around fossil fuels for energy and economic gain, its primary objective has pivoted toward the extraction of materials vital for sustainability. These include minerals indispensable to renewable energy technologies, electric vehicles, and energy storage systems.

This noticeable shift in the motivation behind mining is fueled by the growing recognition of the finite nature of Earth’s resources and the urgent need to transition to cleaner, more sustainable energy sources and technologies. It also reflects an industry-wide commitment to transitioning from fossil fuels to a green economy and environmentally conscious mining practices.

With a surge in demand for special metals used in the production of green technologies, mining has a crucial role in keeping up with the market and contributing positively towards a more sustainable future. In this blog, we’re diving deep into what these metals are, where they’re used, and why the mining industry needs to adapt and extract them responsibly.

1. Lithium

Lithium mining has surged in importance recently due to its critical role in powering the global transition to electric vehicles and renewable energy storage solutions.

Most mines have been extracting lithium using lithium brine extraction, which involves pumping brine from lithium-rich salt flats or saline lake beds into evaporation ponds, where the lithium is extracted. While the method is less energy-intensive than traditional hard rock mining and has a more straightforward waste disposal process, it takes up vast land regions and is ecologically disruptive. Another challenge is the high water consumption associated with brine extraction, which can affect local water resources and ecosystems.

Lithium is, however, proving to be a crucible in which new sustainable extraction methods are being formed. Given its extremely mobile nature, Lithium is often found in geothermal systems, which have the added benefit of supplying heat for energy generation, which can result in barely any carbon emissions for the operation. This method also has a minimal impact on the environment compared to the sprawling salt flats where it is traditionally mined.

The automotive industry’s ambitious electric vehicle production targets are driving exploration into alternative technologies like direct lithium extraction (DLE), which could increase efficiency and decrease the negative impact of the brine mining process. This process produces battery-grade lithium carbonate or hydroxide in a matter of hours without the need to transport concentrated brine to a separate processing facility. DLE is already being used in Argentina and China, where the companies Livent and Sunresin are implementing commercial tech that combines DLE with traditional evaporation pond operations.

2. Cobalt

Cobalt is another metal in high demand due to its use in lithium-ion batteries, as well as the production of jet engine parts, magnetic materials, and pigments. Cobalt is typically extracted using bio-mining, an environmentally friendly method that uses microorganisms to extract cobalt from low-grade ores or mine waste materials.

Cobalt mining, however, has been associated with multiple instances of social abuse, often linked with unethical practices and human rights violations. One of the most concerning issues is the use of child labour in cobalt mines, particularly in the Democratic Republic of Congo. Additionally, miners in some cobalt mines face extremely unsafe working conditions, including lack of protective gear, inadequate ventilation, and exposure to toxic substances, leading to health issues such as respiratory problems and skin conditions.

It’s important to note that efforts are being made to address these issues, such as improving working conditions, enforcing child labour laws, and promoting responsible cobalt sourcing. However, challenges persist, and mines play a crucial role in addressing these challenges through responsible sourcing and advocacy for improved standards and regulations.

https://www.washingtonpost.com/world/interactive/2023/ev-cobalt-mines-congo/

3. Nickel

Nickel, crucial in lithium-ion batteries and superalloys for aerospace and chemical processing industries, is predominantly extracted from laterite or sulphide ores.

Mines are exploring innovative techniques like heap leaching, which dissolves metals from low-grade ores using acid solutions. However, heap leaching raises environmental concerns due to contamination from leaching solutions and chemical waste production, which, even after treatment, contains harmful chemicals linked to respiratory illnesses. There is a need in the industry to implement rigorous environmental monitoring, employ responsible chemical management, and engage with local communities to ensure sustainable and socially responsible mining practices.

Mines can also recover nickel from electronic waste (e-waste), with research now being carried out into possibly mining landfills, which will have the added benefit of addressing legacy pollution issues in some areas.

4. Copper

Copper is one of the critical metals for the green transition. Electric vehicles, for example, use six times as much copper wiring than gas-powered vehicles. Typically found in underground mines, copper is processed in one of two ways: soaking or leaching. However, the surge in the demand for copper has led to the need for innovative new extraction methods to meet the growing demand.

Locus Fermentation Solutions, an Ohio-based chemical business, aims to increase copper production yields by using bio-surfactants from natural sources like yeast. Locus claims that by adding bio-surfactants and other chemicals during the soaking process, more copper floats to the surface, and less is wasted. Urbix, another American startup, uses machine learning to work out how to create uniform graphite anodes fit for use in EV batteries from various natural and synthetic forms of graphite.

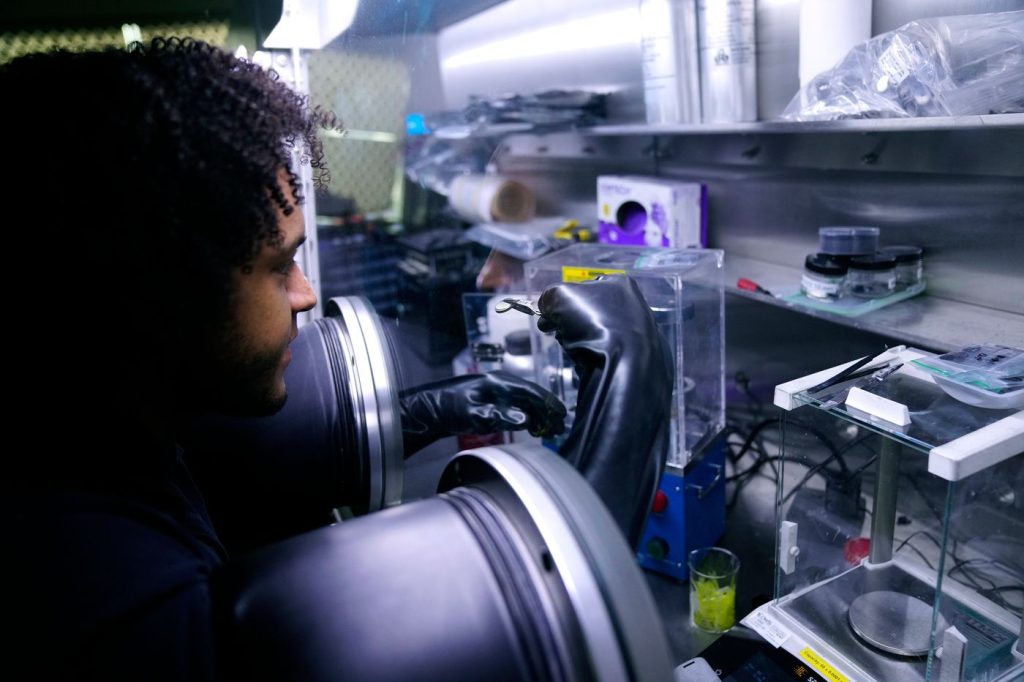

Laboratory testing at Urbix’s plant in Mesa, Ariz. PHOTO: URBIX INC.

5. Rare Earth Metals

Rare earths are now integral to the manufacture of many carbon-neutral technologies, plus a wide range of high-tech applications, including electric vehicles, wind turbines, and smartphones. However, the process of converting the ore to a usable form is often a complex, environmentally hazardous process. Consequently, the rare earth mining industry grapples with a legacy of environmental issues.

Open-pit mining poses environmental contamination risks, and without proper regulation, it can create wastewater ponds containing acids, heavy metals, and radioactive substances that pose a risk of groundwater contamination.

Innovative solutions like bacteria-assisted Rare Earth Elements (REE) extraction and REE recovery from coal ash offer promising alternatives.

Moreover, organisations like the World Resources Institute have been calling for more recycling of existing rare earth materials to reduce the need for new mining and processing.

New career opportunities

The shift in focus from fossil fuels to metals like lithium, carbon, nickel, and other critical minerals is opening up new career opportunities in the mining industry. There is a growing demand for professionals skilled in sustainable mining practices, environmental management, and developing cleaner and more efficient extraction technologies.

Additionally, roles related to battery recycling, mineral exploration for green technologies, and supply chain management for renewable energy industries are rising. As sustainability and responsible resource extraction become paramount, the mining sector offers diverse career prospects for individuals interested in contributing to a greener and more sustainable future.

The Bottom Line

Mines play a crucial role in meeting the demand for metals used in new green technologies, but it also comes with environmental and social challenges that must be addressed.

It’s essential for mines to implement responsible mining practices to ensure that the extraction of these metals is sustainable for both the environment and the communities surrounding the mines.

Have we missed anything out? We look forward to hearing from you!

Author: Subhrata Sinha