Many mines struggle to acurately report on production tonnes vs. targets and mine plans. Click to read more about MTS solutions…

Mine Planning: Easily Capture and Report on Production Targets vs. Actual Performance

For many mines running a Fleet Management System (FMS) along with a Business Intelligence (BI) product such as SAP Business Objects (BO), getting accurate and reliable numbers out of the FMS database isn’t always as straightforward as you think – especially when it comes to tying actual production figures to planned, budgeted production.

The Impact of Data Quality on Mine Planning Reporting

There can be a myriad of nuances to the data generated by mining fleet management and high precision machine guidance mining technology. Although there is a high degree of automation, these systems still rely heavily on human input… and humans frequently make mistakes. When looking at your ‘raw’ database production figures, remember that what you are looking at can be impacted by the following:

- Material overrides by loading tool operators.

- Incomplete cycles and cycle edits.

- Incorrectly configured material sources and dumps.

- Inaccurate onboard hardware (payload monitoring systems especially).

- Mis-matches in naming conventions between the mine planning software and the fleet management system (e.g., blocks and benches named differently between the two systems)

- Misconfigurations between the office software and equipment.

- Poor radio network coverage (which can result in loads being ‘lost’).

- Data quality issues such as future-dated cycles and duplicated information.

Mining Industry Analytics

Efforts at undertaking analytics based on mining technology data can easily be undetermined by the above. This can make fleet management, material reconciliation and mine planning feedback much more difficult than it should be.

In our experience, data quality and data cleanliness issues are further compounded by three further problems that typically arise at many sites:

1. Most operations run different planning systems; combining actual production data can be difficult as there are no ‘off the shelf’ solutions to tie this to fleet management system data to mine planning and target data.

2. Workarounds are commonly put in place tying a BO report to an Excel ‘target’ data source. This kind of workaround requires almost constant maintenance and frequently breaks… We have lost count of the number of broken spreadsheets that we have encountered over the years!

3. Actual operational performance data is exported from the BI product into Excel, where budgets/targets are copied in from another document. This is both time consuming and can very easily lead to errors. Often we see different calculations depending upon which version of the spreadsheet is used.

When integration with the planning system isn’t an option, the use of a centralised tool is preferred for controlling targets. This ensures only one version is maintained in the correct format, rather than multiple different spreadsheets being emailed around.

Simplified, Automated Mine Planning Reporting

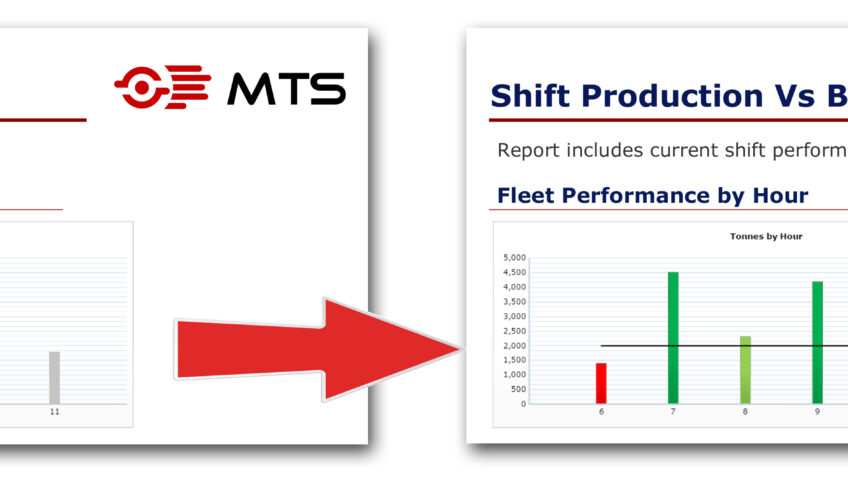

In response to this challenge, we built a highly configurable form-entry system, ‘Reporting Enrichment Forms‘ (REF). REF can be used to augment and improve short term, medium-term and long-term mine planning, provide flexible targets for short interval control dashboards and mine reports for Mine Operations and Mine Maintenance.

REF is designed to be configurable for each mine’s specific business requirements and data is written to a secure database, hosted within your company’s existing network and data structures. No maintenance is required, other than somebody to enter weekly or monthly values, according to what is needed at your mine.

Data is entered manually (such as target tonnes for bench 1100 for January 2017), meaning that it is able to be standardised and reliably tied to actual production in an automatic scheduled BO report, mining dashboard, etc… Simple!

Any changes made within REF are immediately reflected in any subsequently run reports, dashboards, etc. This makes it quick and easy for any authorised person to make changes without having to re-work multiple business intelligence visualisations.

With over a dozen REFs now deployed at mines worldwide, we’ve found this method saves time, reduces mining reporting errors, and helps automate a major pain point for mine site reporting teams. It is also an incredibly simple and effective way to decrease mining report costs and improve understanding how progress towards mine planning targets.

Beyond just targets vs. actual production we’ve also used this method to allow operations to report and control many other items:

- Company KPI targets required for mine reporting vs. actual operational performance in mining dashboards.

- Dispatchers entering in ‘comments’ about the shift to provide extra context for historical reporting (e.g. “Loading slow due to poor blast fragmentation”).

- Entry of operational data for equipment not fitted with an FMS system. (e.g exploration drill activity currently relying on paper entries converted to XLS).

- GET (tips) Wear tracking and comparison.

- Grouping of engines and assets under specific roles/regions to allow easy reporting and mining industry analytics.

To learn more about our mining consultancy services and mining industry solutions & projects, please contact us here.

#productiontargets #FMSproductiontargets #KPImanagement

[DISPLAY_ULTIMATE_SOCIAL_ICONS]