Creating the zero-carbon mine

Creating the zero-carbon mine

Short, medium and long-term goals for mines to achieve carbon neutrality

With the global shift towards climate consciousness, industries across domains are being compelled to make significant operational changes in order to remain relevant. Amid this transformative landscape, the mining sector is under increasing pressure to reduce its carbon footprint.

The mining industry’s strive towards carbon neutrality is a challenging one, which requires a long-term strategy that includes short, medium, and long-term goals.

Short-term goals:

1. Reduce idling time

Mining equipment often idles when not in use, thereby wasting fuel and producing unnecessary emissions. Fuel consumption can be minimised by investing in automation and remote control technologies.

For example, some mines use automatic engine shut-off systems which turn off equipment when they detect inactivity. This is especially useful for equipment wasting fuel while waiting to load or unload materials.

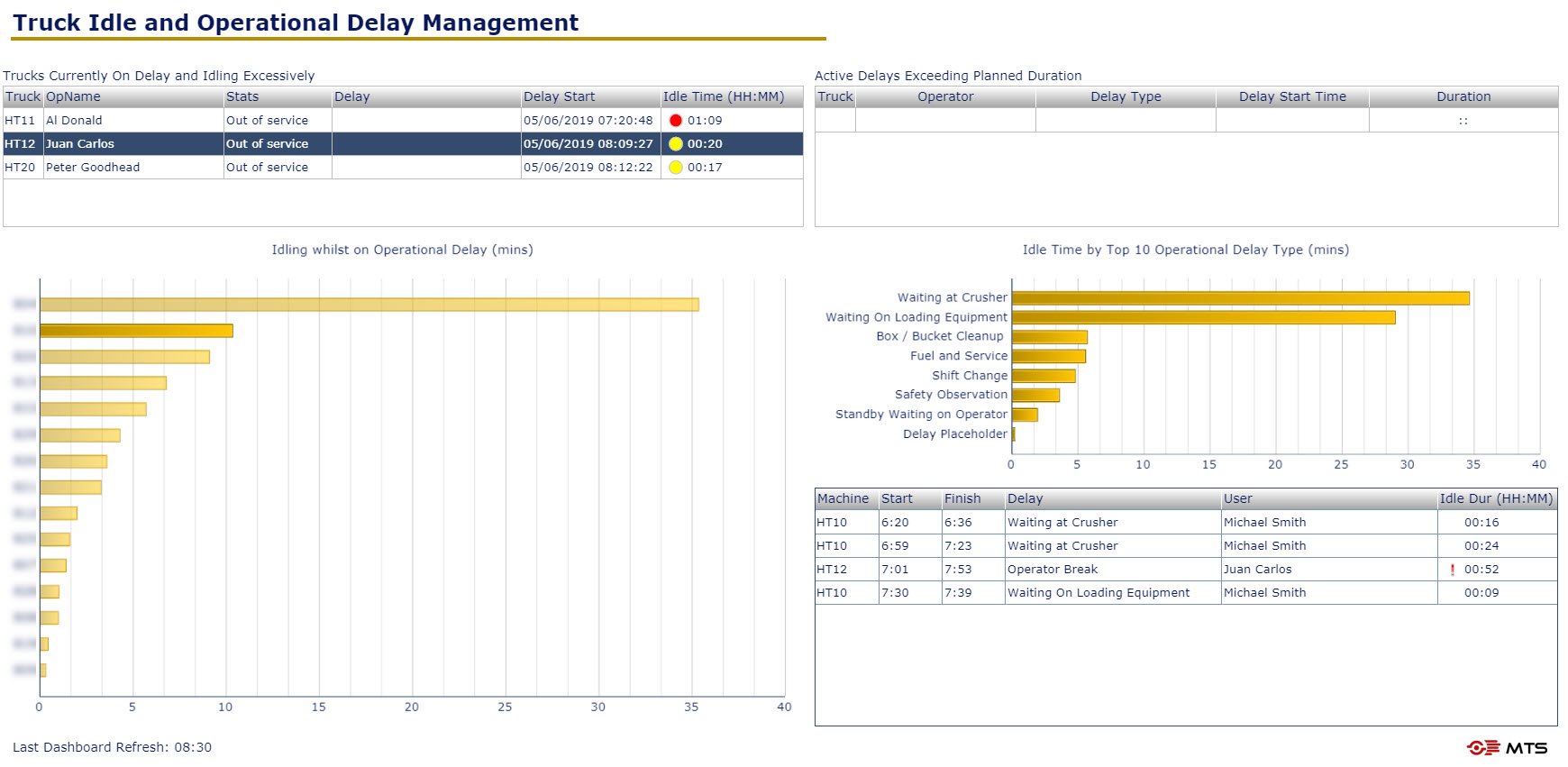

As part of a larger mine optimisation project in an open pit-mine in America, MTS was engaged to help target and manage mobile equipment idling. Analysis showed that one of the sources of delays (amongst others) was from operators idling their machines when they should in fact be turned off (eg. lunch breaks). It was decided that to actively manage this behaviour, live dashboards would be required and the on-shift dispatchers would be tasked with monitoring operators.

Live dashboards use to monitor and reduce idle time at an open pit mine in America

Following Mine Tech Services’ deployment of the solutions, as well as mentoring with the team members, there were significant reductions in idle time particularly during delays. Within 3 months of the solution deployment, the idling on delay was reduced by 50% and maintained at this level.

2. Optimise routes

On sites, mining equipment often needs to travel long distances, leading to increased fuel consumption and emissions. With the use of sophisticated route optimisation software and geographic information systems (GIS), mines can optimise routes to cut down on travel time and fuel usage.

Real-time tracking and monitoring systems now allow mines to supervise a vehicle’s location and condition remotely. This allows for on-the-fly route adjustments based in response to unforeseen conditions or occurrences, like road closures or traffic jams.

Moreover, simulations allow mines to identify the most effective route adjustments before implementing them.

3. Implement eco-driving practices

Mines can also reduce fuel consumption and carbon emissions by encouraging eco-driving practices, such as reducing speed and avoiding sudden acceleration and braking. Care should be taken to load vehicles within their recommended payload limits as overloading not only increases fuel consumption, but also increases wear on the equipment.

By adequately training operators on eco-driving techniques, mines can help drive a culture of climate consciousness.

4. Implement energy-efficient practices

Energy-efficient practices, such as using LED lighting and energy-efficient HVAC systems, can help reduce energy consumption and carbon emissions. Mining companies can implement energy-efficient practices in their mobile equipment to achieve carbon neutrality.

Trolley assist, for example, can offer significant benefits to mines by providing an innovative and efficient solution for the transportation of materials, while reducing environmental impact. By utilising electric power instead of relying solely on diesel engines, trolley-assisted trucks can significantly reduce fuel consumption and help mines meet sustainability goals. This can also lead to substantial cost savings in fuel expenses, contributing to improved operational efficiency and profitability.

Cat 795 AC mining truck on trolley at Boliden Aitik mine

Medium-term goals:

1. Use of BEVs or hybrid technology

With diesel-powered vehicles accounting for 30-50% of greenhouse gas emissions on site, the switch to an alternative medium is critical to creating a zero-carbon mine. While both hydrogen fuel cells, as well as BEVs offer potential solutions, hydrogen technology is yet to gain traction, making BEVs the best solution for now.

By using BEVs, mines could significantly save on ventilation and cooling costs, while ensuring improved worker health. Battery vehicles also have fewer parts, consequently leading to lower maintenance costs and lower noise pollution compared to their traditional counterparts.

An example of BEVs’ successful deployment is the Newmont Goldcorp’s Borden Lake mine in northern Ontario.

Alternatively, mines could also consider implementing hybrid technology, which offers the flexibility to switch between electric and conventional modes of operation, depending on the task and operational requirements. This versatility helps optimise fuel efficiency and reduces the need for continuous fossil fuel consumption.

2. Use renewable energy sources

Mining companies can use renewable energy sources to power their mobile equipment. Renewable energy sources, such as solar, wind, or hydroelectric power can be used to generate electricity to power equipment on mining sites.

Integrating renewable sources of energy into mining operations requires careful planning, investment, and collaboration with experts in the field. While the upfront costs may be significant, the long-term benefits, including reduced operational costs, improved sustainability, and a smaller environmental footprint, make renewable energy a compelling choice for modern mining practices.

Long-term goals:

1. Carbon offset programs

Carbon offset programs offer strategies aimed to help mines compensate for their greenhouse gas emissions, while maintaining their operational activities. The goal is to achieve a net-zero or reduced carbon footprint for the mining operation.

By partnering with reforestation efforts, renewable energy projects, and other environmentally beneficial activities, mines can not only demonstrate their commitment to responsible operations but also play a pivotal role in global efforts to combat climate change.

Moreover, carbon offset programs can help mining companies achieve emissions reduction goals mandated by regulations and industry norms. The Gold Standard is a certification that ensures carbon credits are real and verifiable, and that projects meet high-quality standards.

2. Optimising processing plants

On mine sites, generally over 50% of the energy used is spent on crushing rock in the processing plant. In fact, 3% of global energy production every year is used to crush rock. This provides possibly the biggest challenge to a carbon neutral mine. However, with this challenge there is also a wealth of opportunities for improvements. Mills are constantly being improved to increase efficiency. Also by utilising technology in the rest of the operation to optimise feed into the mill, efficiency can be improved further.

For example if waste material accidentally enters the mill feed, it will be crushed needlessly for no value or benefit. The same can be done with optimising drill and blast to result in material clast sizes that are optimum for the mill to process. Generally larger boulders take more energy to crush and break down. However in AG mills, variability across clast sizes is actually required for optimum performance).

In conclusion, achieving carbon neutrality in the mobile mining industry requires an ambitious goal, immediately as well as in the long-term. As we’ve delved into the strategies, technologies, and transformative steps that pave the way to this ambitious goal, it’s evident that achieving carbon neutrality is not just an aspiration, but an imperative.

By embracing innovation, adopting renewable energy, optimising operations, and engaging in carbon offset initiatives, the mobile mining industry can mitigate its environmental impact, while also charting a course towards a more responsible and harmonious coexistence with our planet.

Contact us to find out more about how MTS can help make your operations more efficient and sustainable.