MTS discuss 7 ways that fleet management system reporting can be made more effective at your mine.

7 Ways to Make Your Mining Fleet Management System Reporting More Effective

Until very recently, reporting ‘actual’ numbers and other data from mining technology has often been an afterthought for the many mines who chose to install these systems. Even more so for the sites who are already running mining fleet management, condition monitoring or high-precision machine guidance systems.

This is not necessarily the fault of the mines themselves. There are now perhaps several ‘high’ profile brands of mining technology manufacturers, who sell these solutions on the promise of increased productivity and reduced operating costs.

Whilst this is absolutely true (yes – they do work!) in many cases we find that the OEM’s do not factor in (or make clear) the kind of comprehensive training, change management and technical skills that are required to embed and maintain mining fleet management systems, and then subsequently manipulate the incredibly rich datasets to streamline mining operations.

Mining Industry Development

We have visited dozens of mines where frustrated mining management is still struggling to access the critical data that they need to make important business decisions, even after many months have passed since the initial installation and site configuration of their shiny new mining technology.

After the big rush for new technology in mining, including IoT devices in mining equipment and the ability to ‘get connected’, sufficient attention was not always paid by the OEM’s to how customers would be able to extract, manipulate, distribute and present this data using the skill sets available on-site or in the wider industry in general. Highly-skilled database architects and administrators or Business Intelligence experts are not commonly found on mine sites!

Luckily, due to some of the issues discussed above, we are seeing signs that the problem of getting data out of a mining fleet management system is beginning to become increasingly important to manufacturers, perhaps in part due to increased levels of push-back from their customers.

Mining Fleet Management Reporting: Best Practices

The advent of Mining 4.0 means that industry trends are now all firmly moving in the direction of advanced analytics. Whilst this is extremely laudable, we would recommend that before attempting to implement expansive, complex and expensive programs based around predictive analytics and AI, mines should focus first on getting the basics of mining fleet management reporting ironed out first.

Below we outline some of our mining consulting tips on how to get started with improving your mining fleet management reporting.

Establish Trust in Your Mining Technology Data

This can be a significant hurdle.. We all know that mining engineers love their Excel spreadsheets, but these are simply not suitable for analysis fleet management system data that can be in the order of millions or even billions of rows. Start getting your mine used to trusting the data with some initial “Data Validation” reports which clearly show mining cycle data and any applied calculations (e.g. KPIs). The sole aim of these types of mining reports should be to achieve and maintain interdepartmental confidence in the fleet management system data.

Engage in “Requirements Gathering” with Downstream Recipients

Think of these are your “customers” and have conversations with them about what would best suit their needs. This process can be quite difficult, as people are often stuck in a mentality of wanting lots of data that they can pull into Excel. This mindset can initially be difficult to manage, but remember that to begin harnessing millions of rows of fleet management system data, people will need to get used to the fact that this simply cannot be done in Excel.

Product demonstrations, whiteboards and pieces of paper(!) are all great collaboration tools that will help accomplish firm requirements.

Use the ‘Right’ Reporting Medium for Mining Fleet Management Data

PDF reports or Excel sheets delivered via email really aren’t always the best way of presenting data.

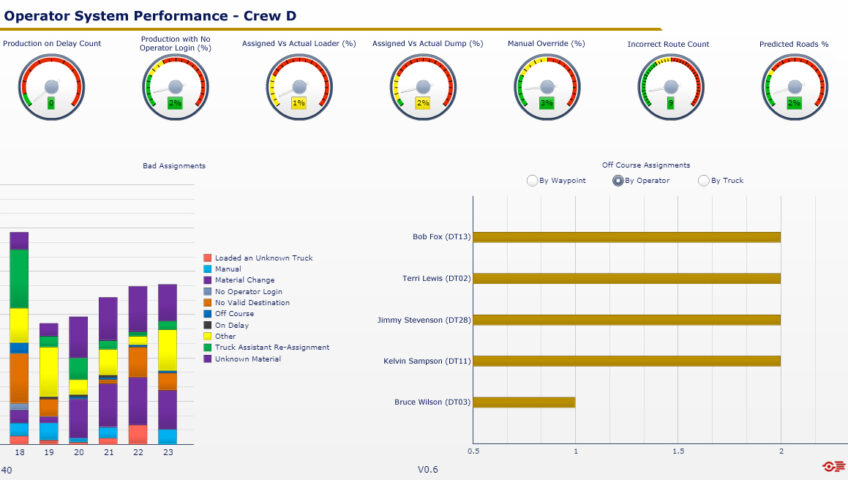

If you are planning on using your mining fleet management system data to build short interval control tools, perhaps consider whether dashboards (desktop or mobile/tablet-based) might be the best way to communicate with users. A dashboard showing at-a-glance production KPIs for the current shift is much better than forcing the user to run and rerun a report every time they need to get a handle on the latest statistics.

Alternatively, if you intend on using your mining technology data for ‘drilling-down’ into multiple issues, consider creating a Business Objects Explorer or Tableau workspace, as these are much more flexible for this purpose.

Timeliness on Delivery of Reporting Solutions

It is important that after Requirements Gathering, a clear path to project completion is communicated to all stakeholders. Emphasis should always be placed on making sure priority reports are produced first. Keeping the team engaged will mean that they are more likely to see potential and the subsequent value of any mining reporting or mining dashboard solutions that are created.

Be Honest About Limitations

Don’t mislead people about what is possible, and about what can realistically be achieved. This avoids disappointment later on and means that future initiatives are more likely to be backed by the stakeholders.

Continuously Improve your Mining Fleet Management System Reporting

Iterate, adapt, and continuously improve on your initial deliverables so that the content remains relevant as the business environment changes.

Don’t be afraid to fail! Failure is a really valuable part of any development process, and will only help you improve the skills of your team in the long-run. Always strive to do better and constantly look for ways to improve your set of mining technology reports and dashboards.

Finally, don’t be afraid to retire previous visualisations that no longer meet business priorities – perhaps two years ago, the focus from the mine operations team was all centred around ore-control, yet this year it could be all about haul road analysis.

Build Quality Mining Reports

We’ve seen some really poor quality ‘canned’ reports from mining technology manufacturers. These erode confidence in the quality of the data, and they make it harder for the end users to understand which information is relevant. Mining reports and dashboards should be easy to read and look professional.

So often report writers will spend hours building a report with complex SQL and formulae; and then fall over at the final hurdle with a report that looks terrible and becomes consigned to the Recycle Bin…

If you are still struggling, don’t worry – help is at hand!

MTS specialise in delivering business intelligence solutions for all major mining technology brands. To learn more about our mining consultancy services and mining industry solutions & projects, please contact us here.

#changemanagement #strategy #reporting #continuousimprovement

[DISPLAY_ULTIMATE_SOCIAL_ICONS]