5 Pitfalls to Avoid when Developing Mining Operator Scorecards

During the pandemic, many mines struggled with significant staff absences. Consequently, those remaining onsite became overstretched filling the void. Many initiatives to boost productivity often got dropped as operations simply tried to get enough resources to operate the fleet.

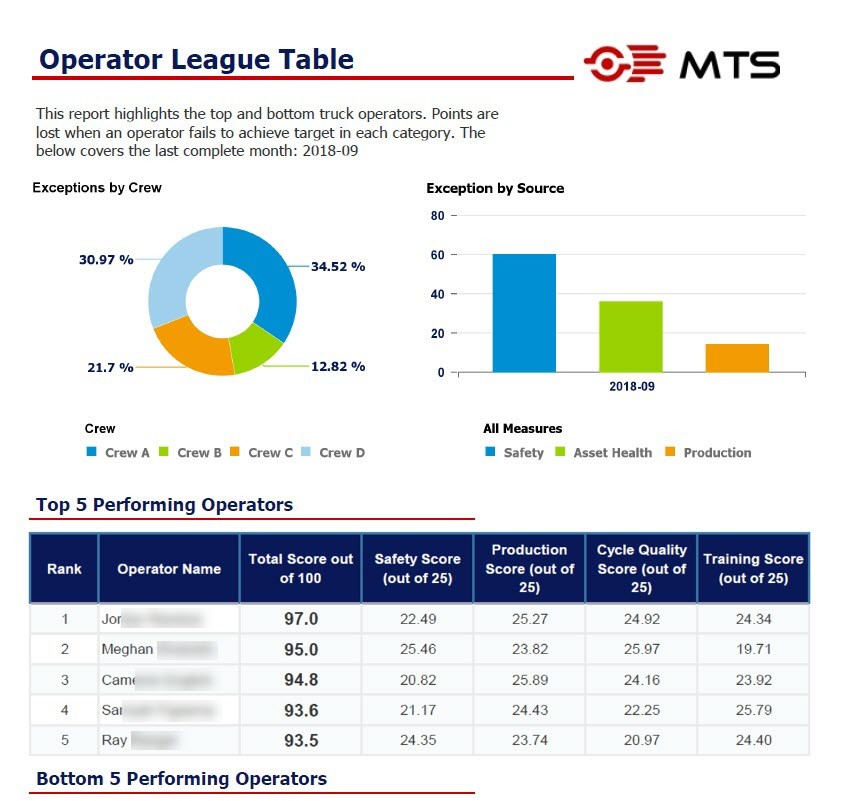

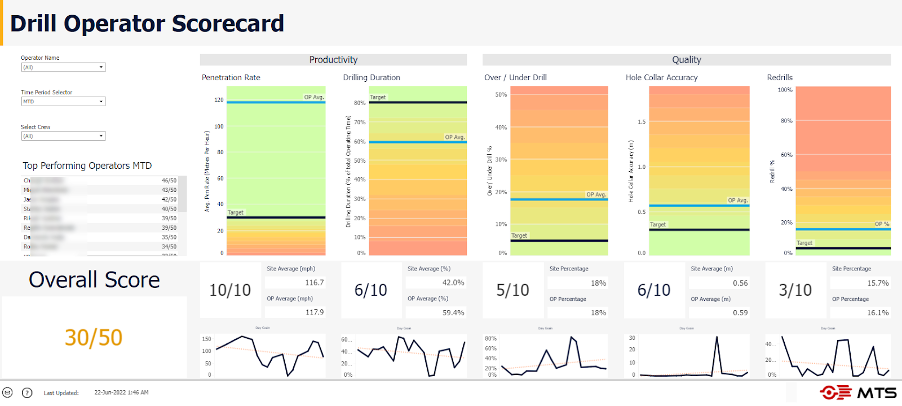

With the impact of COVID-19 receding, operations are now beginning to refocus on optimization (and in some cases, pushing to autonomy). The Mining Operator Scorecard is one tool that mines are increasingly using to benchmark individual performance.

Whilst such an initiative sounds simple, it isn’t. Every site we’ve encountered wants to adopt a different approach, and we continue to see operator scorecards that don’t deliver the expected results.

As we help mines develop and implement balanced scorecards that are successful, we take a look at the Top 5 common traps for operations to avoid…

1. KPIs that drive the wrong behavior

Time and again, we have seen that a very limited (and poor) selection of KPIs tends to drive the wrong behavior.

For example, by focusing only on a few production KPIs in their operator scorecards, some operations compromised both safety and equipment health. In other instances, loading tool operators were penalized for loaded haul speeds, which is out of their control. Our favorite example is a site that was scoring operators on utilization; What did they do in response? Run all the equipment regardless of need and avoided using stoppage codes simply to achieve maximum utilization numbers!

It is very important therefore that a balanced set of relevant KPIs are agreed upon for the scorecards to drive the right behavior. In some instances, this may mean splitting up scorecards to make them role-specific, for e.g., Loading tool operator Vs Truck operator Vs Crew Supervisor.

Operator Scorecards must include a balanced set of KPIs to drive the right behavior

2. Complexity and Buzzwords

Getting the right KPI leads us to our second point, which is to avoid unnecessary complexity. While this is particularly important in countries with lower literacy rates, it applies to all sites. Having dozens of KPIs or very abstract/complicated KPIs can cause confusion and ultimately switch off your audience.

Using buzzwords that are unclear is a sure-fire way to disengage the team on the ground. Stick to plain, clear language that everyone understands (and respects). If needed, include a description in the supporting documentation.

3. Lack of awareness of the Audience’s Culture

Every mining operation is different. Moreover, there are regional and cultural variations, as well as different laws governing personal data. In some jurisdictions, unions can have a greater say in how an operator can be benchmarked.

It is therefore important to ensure that your mine’s scorecards are designed and delivered in a way that will have the maximum impact without causing any unintended consequences.

4. Lack of Ownership and Accountability

Once scorecards are agreed upon, developed, and implemented, they become totally redundant if nothing is done with the insights they provide. As part of the change management process, a clear set of roles and responsibilities should be defined. This helps sites identify, acknowledge, and potentially replicate the top performer’s behavior, thereby driving a positive team culture, while identifying areas for improvement.

Ideally, some form of task tracking should be used so that accountability for coaching operators is maintained. Also importantly, the site leadership team should have visibility to trends so that they can see performance and long-term results.

Task tracking is essential to ensure that accountability is maintained

5. Manual Reporting is a drain on site resources and will lead to failure

Finally, but of great importance is the plan to regularly create/update scorecards while avoiding a lot of manual reporting work. When this is not automated, scorecards can be extremely time-consuming, prone to inaccuracy or bias, and will likely stop working when the spreadsheet guru running them moves into a new role. Also, with manual processes, accessing and viewing scorecards can be time-consuming, making it difficult to quickly review and take corrective action.

With modern machines (fitted with many sensors), fleet management systems, and business intelligence tools such as PowerBI or Tableau, there should be no excuse for scorecard content being manually prepared. Continuing to do so manually is a guarantee that the initiative will fail in the long term.

At MTS, we have many years of experience in developing and implementing balanced scorecards for mines, that drive meaningful results. Change management is always key!

To find out more, drop us a line here.