Transform Haul Road Safety Now with Proven HRE Solution

HRE resulted in a 36% reduction in abusive truck operation alarms, a 29% reduction in road-related incidents, a 44% reduction in road-related alarms, and significantly improved overall safety and asset performance.

HRE resulted in a 36% reduction in abusive truck operation alarms, a 29% reduction in road-related incidents, a 44% reduction in road-related alarms, and significantly improved overall safety and asset performance. The Task

A mature gold mine with an extensive road network used Haul Road Explorer to transform the way they operated. This case study explores a safety incident at this gold mine and how Haul Road Explorer (HRE) software was used to identify the root causes and implement corrective actions. They transitioned from reactive road repairs to proactive planning, resulting in significant improvements in safety and haulage performance.

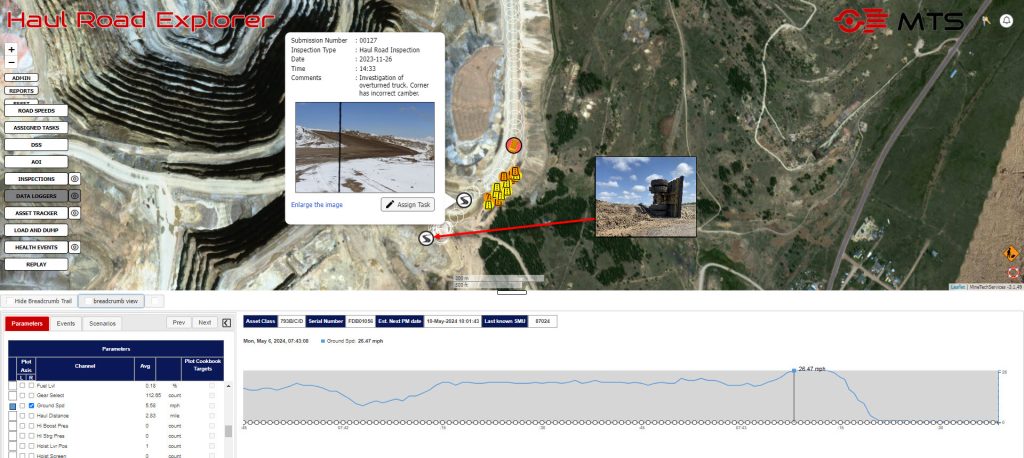

A safety incident occurred when a haul truck slid off the road and overturned. The site had concerns about road design, maintenance, and asset operation. They wanted to utilise HRE to conduct an analysis of the root causes of the incident.

Traditional investigations for these type of incidents can be time-consuming, and involve:

- Gathering information from witnesses and reviewing CCTV footage.

- Analysing data from the truck’s dataloggers.

- Physical examination of the incident area.

This process can take hours, delaying production and the implementation of corrective actions.

The Solution

How HRE Expediated the Investigation

The site had HRE operational and wanted to analyse the data relevant to the event to better understand the situation. HRE was adopted to investigate traffic flows, asset health and operations around the time of the incident.

- HRE’s replay tool was used to replay operational movements. It determined that there were no other vehicles in the vicinity, insinuating the event was not due to traffic or interfering machines.

-

Machine health events were plotted and analysed for both the truck involved in the accident and the parts of the fleet that were near the location of the incident. This was to try to determine whether this was either a machine-specific issue or due to site ground conditions. From this analysis, it was determined:

-

- The truck involved in the incident had no health indications causing concern around the time of the incident.

-

- Several bias and traction events from a number of trucks were indicated near the bend where the accident occured.

HRE analysed the data from the truck’s dataloggers, including suspension condition, ground speed, brake application, steering inputs, and other relevant factors, in order to determine operational parameters leading up to the incident. This analysis determined:

-

- The speed and payload of the truck exceeded the road limits in the bend.

- A heavy load on the singular side of the truck’s suspension when going around this bend. This was also visible for other trucks travelling this route.

A physical visual ground inspection was conducted in order to better understand site conditions in relation to the prior findings. The investigators saw:

-

- An adverse road camber on the bend was causing one-sided heavy suspension pressures and bias alarms. This was due to an old junction in the vicinity.

- The section of road appeared to be heavily saturated, highlighting inadequate drainage and water management. This was predominantly because of the seasonal transition from winter to spring, when there are typically high levels of melting snow.

-

Corrective Actions

After the swift determination of the root causes of the incident, preventative measures could be taken to ensure this event would not reoccur:

- Road Closure and Re-engineering: The road was closed and re-engineered to include the required superelevation and improved drainage.

- Weekly Planning: The site incorporated a focus on roads and operator issues in their weekly planning meeting.

- Operator Training: Additional training was provided to operators. This training focussed on safe driving practices, particularly in areas with adverse road conditions.

The Results

- Rapid root cause analysis to determine the causes of the incident

- 36% reduction in alarms related to abusive truck operation.

- 29% reduction in incidents related to road conditions.

- 44% reduction in alarms related to road conditions.

- The overall safety of the operation was significantly enhanced due to the corrective actions.

- Improved road conditions and operator training contributed to better asset utilisation and reduced maintenance costs.

Summary

By incorporating HRE into site processes and incident investigation, the site was ultimately able to:

- Conduct Rapid Incident Investigation: HRE streamlined the investigation process, reducing downtime.

- Utilise Data-Driven Decision-Making: HRE provided valuable data for informed decision-making.

- Improve Asset Operation: Corrective actions led to improved road conditions and a safer operation.

- Enhance Safety: The overall safety of the operation was significantly enhanced through proactive measures.

- Achieve Cost Savings: The reduction in incidents and downtime resulted in cost savings for the mining operation.

This case study demonstrates the value of HRE in identifying root causes and implementing effective solutions to improve safety and operational efficiency. By leveraging data-driven insights, mining operations can enhance asset performance.