World Class Service Accuracy Performance

Increased Service Accuracy from 70% to >95%

Increased Service Accuracy from 70% to >95% The Task

The Solution

The Results

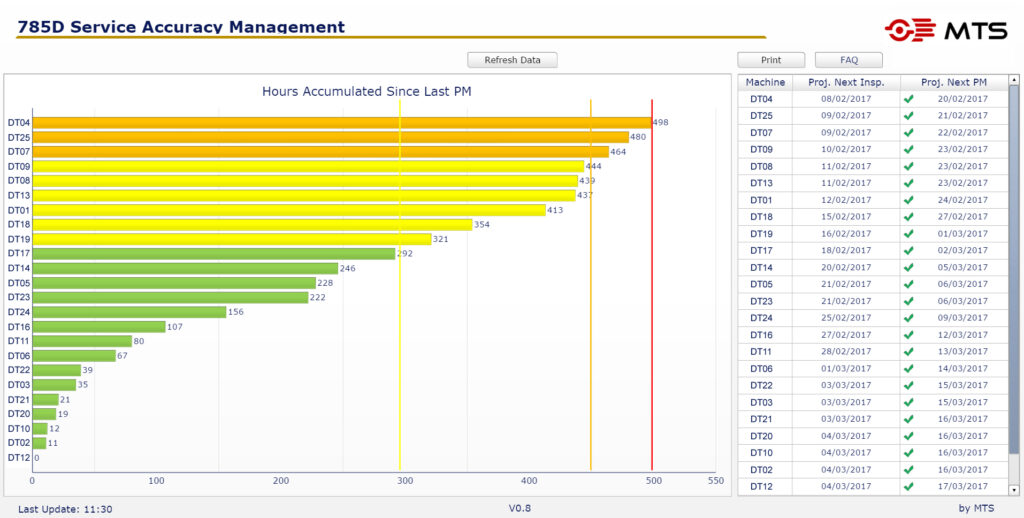

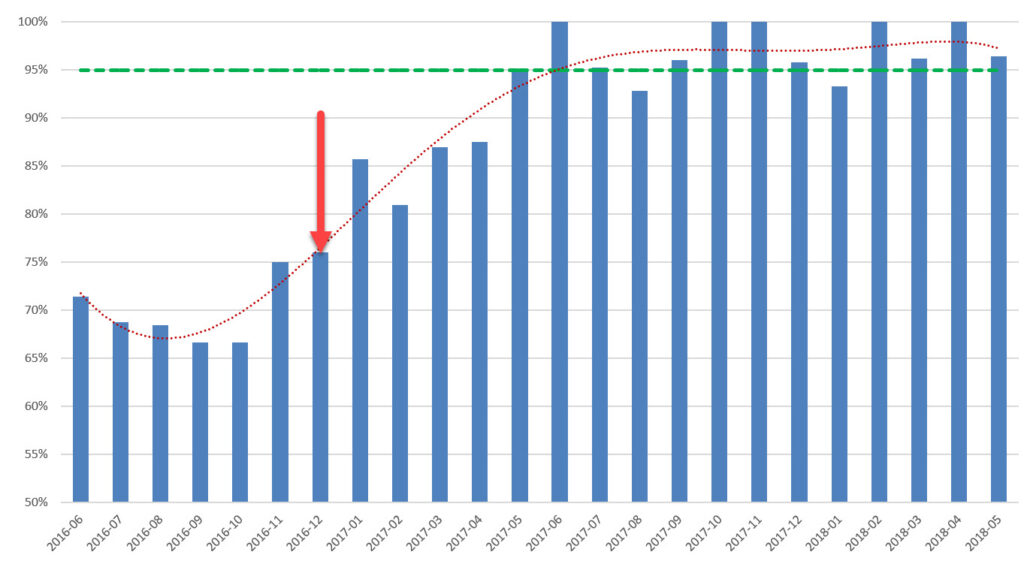

The increased visibility of the PMs, as well as the more effective use of AMT, enabled the team and supporting functions to greatly improve the Service Accuracy performance. As the hour entry and PM planning process was more automated it also reduced the man-hours required, allowing the planning team to focus efforts on other priority tasks.

The below illustrates when the solutions were developed and deployed, and the change management process was started with the teams. Within 6 months the site was able to achieve and maintain a world class average of>95% for their truck fleet. This positively impacted the overall availability of the fleet.

Additionally, as the accuracy improved, other functions used this to plan more effectively. The condition monitoring team would consolidate onboard troubleshooting and diagnostics, if possible, to these PM stoppages where historically they may have stopped the machine. Also, the production team were more confident of when assets would be removed from them for servicing.

Based on the successes of this project the site looked for further solutions with MTS to predict other service activities the planned component change outs (PCRs). This focussed on an increased set of parameters including SMU Hours, fuel consumption and asset condition.

Summary

MTS delivered considerable improvements in a short execution time. This was due to the combination of in-depth asset health and maintenance planning knowledge as well as the ability to access and automate the required data.

This case study demonstrates how a focussed project can quickly result in significantly increased performance.