Optimised Refuel Assignments

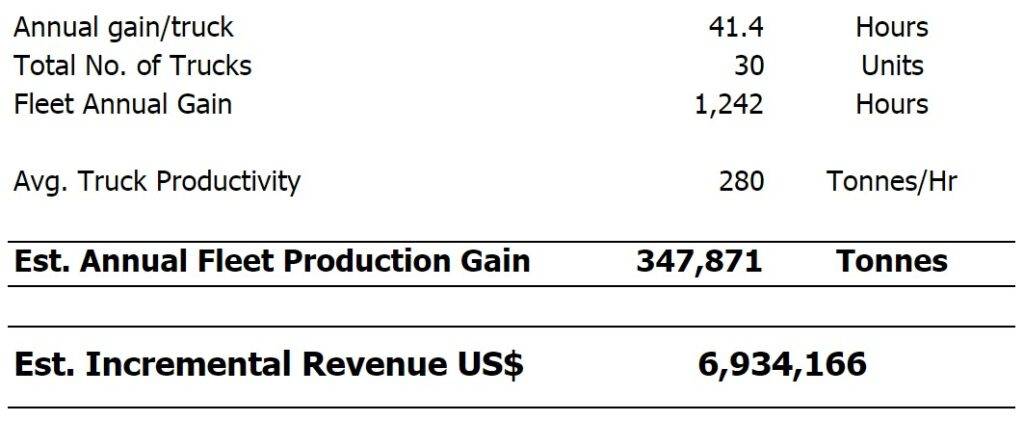

Increased production by 350,000 Tonnes per year (incremental revenue of ~US$5m)

Increased production by 350,000 Tonnes per year (incremental revenue of ~US$5m) The Task

A large gold mining company operating in South America engaged Mine Tech Services to optimise their use of the Cat MineStar Fleet management system in order to improve truck productivity and reduce material dilution.

Part of this project focused on the optimisation of fueling activities. The two core objectives were to make truck fuelling assignments more efficient in order to increase working time between refuel stoppages and to spread out fuel times across each shift to avoid queuing and subsequent loss to production.

The Solution

A full system audit of the operation was conducted to assess how efficiency could be improved. It was noted that dispatchers and truck operators were responsible for deciding when a machine required refuelling. Under this method, the timings of fuelling assignments were suboptimal, resulting in lost production hours.

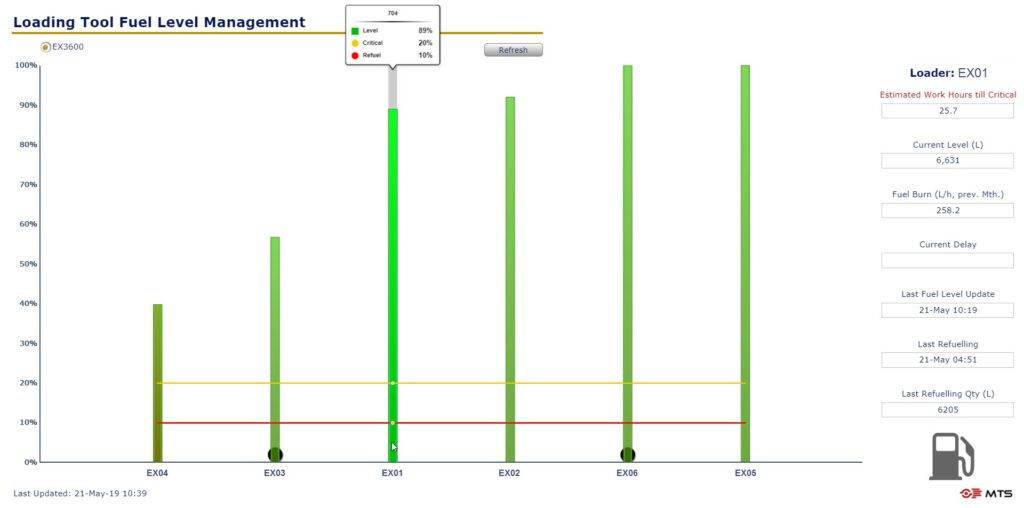

To resolve this, the site’s Fleet Management System was configured to schedule truck fuelling assignments automatically. Refuel thresholds used for the assignment engine were refined and validated based on tank capacities and operational needs. Custom dashboards were created which displayed fuel levels and the estimated time until refuel. This improved visibility for the dispatchers and also enabled the fuel and lube truck crews and maintenance teams to determine opportune times for refuelling the tracked fleet and consolidate minor maintenance tasks. This resulted in fewer and shorter delays, improved assignment timings and increased production hours.

Training for key personnel and on-the-job mentoring were provided by Mine Tech Services throughout the process.

The Results

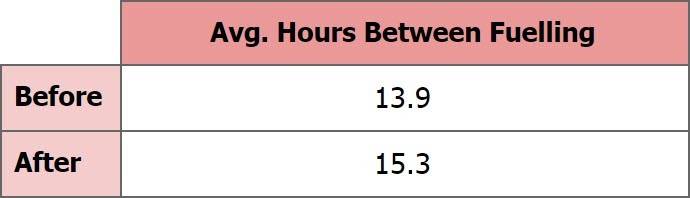

Following Mine Tech Services’ deployment of automated fuelling assignments, hours available between fuelling cycles at the operation increased by 10%:

In addition, time spent waiting for fuel reduced by an average of 40 hours per month per truck. Over a one-year period, this is equivalent to over 1,250 additional hours of production for the fleet, equating to over 350,000 extra tonnes:

Summary

This case study demonstrates how automatic fuelling assignments can be a low-cost and high-impact way to generate value from existing capabilities.

By assessing and adjusting existing fleet systems and processes – and by developing existing skills through training, mentoring and benchmarking – Mine Tech Services substantially increased the operations available production hours with minimal capital outlay.