Case Studies

Idle Time Reduction

Type: Productivity

Site: Open Pit Mine

Location: America

Outcome: ↑ 60% reduction of idling on delay

The Task

Part of a larger mine optimisation project called out the reduction of idle time as one of the key areas for improvement. MTS was engaged by the client to help them target and manage mobile equipment idling. They were keen for us to provide insight as to where idle time could be reduced without simply applying blanket policies which may impact production.

The Solution

Idle time is unavoidable for mining operations, however, it can be targetted and minimised in many areas.

1. Identification of avoidable idle time

Before trying to tackle idle time as a whole it was necessary to understand the source and reasons for excessive idling. The purpose of this analysis was to isolate specific areas, define targets and build processes, procedures and management tools.

The largest opportunities for reducing idle time for this particular site came from how the operators went on delays. There were a significant number of occurrences where operators idled their machines during delays where the machine should be powered off (e.g. lunch). Another area was the length of delays taken as well as the total duration of delays, For example, one operator taking 5 coffee breaks taking totalling 48 minutes – when only 2 totalling 30 minutes are allowed.

It was decided that to actively manage this behaviour, live dashboards would be required and the on-shift dispatchers would be tasked with monitoring operators. Management would intervene with non-compliant or chronically poor performers.

2. Standard Operating Procedure Creation

Business definitions were built around the identified areas of when idle would be considered to be excessive. The included the roles, responsibilities and empowerment of certain roles to deliver the results required.

3. Management Tools & Mentoring

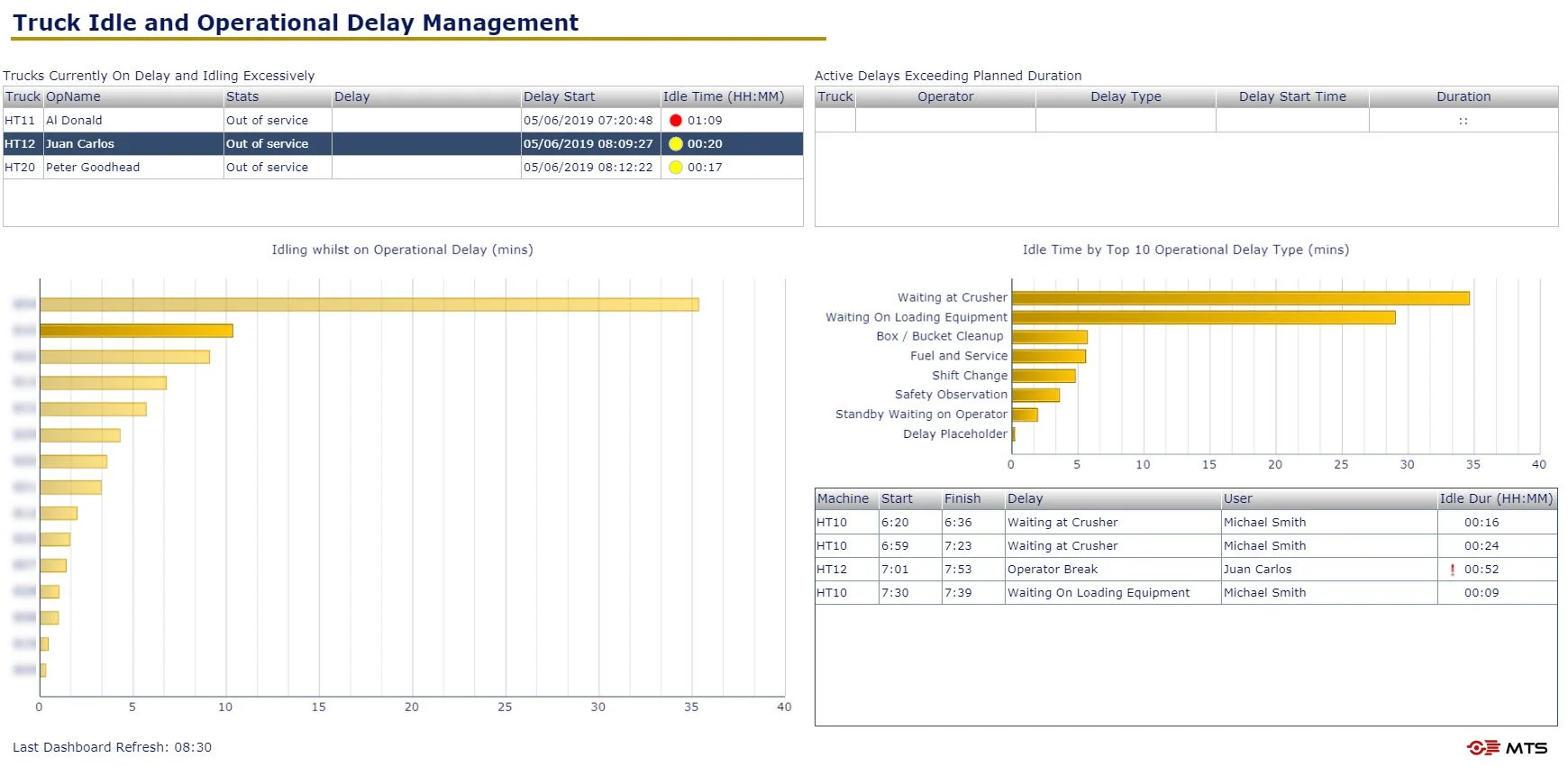

The business definitions for excessive idle were coupled with operational data from the Cat MineStar Fleet system and built into several reports and dashboards. An on-shift dashboard captured the key metrics and allowed the on-shift team to communicate with operators about their behaviour.

This real-time management of idling was summarised in regular reports for the management team to identify overall crew performance and trend of behaviour.

As the crews were able to tackle excessive idling immediately rather than at the end of the week/month etc. results were very quickly seen.

Truck idle time and operational delay management dashboard for mining operations developed by MTS

The Results

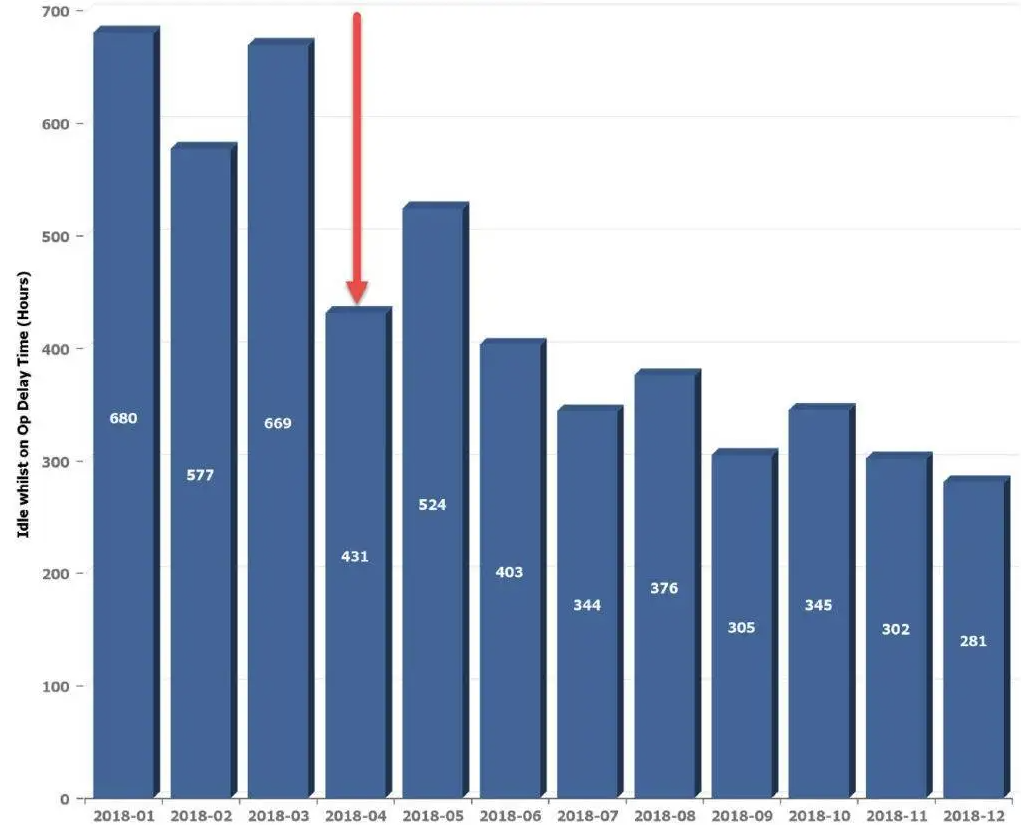

Following Mine Tech Services’ deployment of the solutions, as well as mentoring with the team members, there were significant reductions in idle time particularly during delays. Within 3 months of the solution deployment, the idling on delay was reduced by 50% and maintained at this level.

Summary

MTS was able to help the site take a broad, high-level initiative and target key areas they could tangibly work on and measure their effectiveness. With the solutions deployed they have not only been able to achieve significant improvements but also maintain them after MTS left site.

Why Choose MTS for your Mining Technology Needs?

At MTS, we bridge the gap between mining technology, people, and IT. Our experienced team of mining technologists is dedicated to empowering mines to enhance productivity, minimise waste, and optimise costs through the seamless integration of technology.