Case Studies

Mitigating Operator Equipment Abuse

Type: Asset Health

Site: Surface Mine

Location: West Africa

Outcome: ↑ 37% decrease in frame cracks, 56% reduction in alarms triggered by improper equipment operation

Resource Type: Asset Health

The Task

Operator equipment abuse presents a significant challenge to any mining operation. This behaviour can have significant knock-on consequences, including:

Premature Component Failures: Improper handling techniques can lead to excessive wear and tear on equipment components, resulting in premature failures. These breakdowns disrupt production schedules, causing delays and potential revenue losses.

Increased Maintenance Costs: More frequent equipment failures translate to a higher workload for maintenance crews. The associated costs for repairs and replacement parts can significantly impact a mine’s operating budget.

Safety Hazards: Operator abuse can compromise equipment safety features and increase the risk of accidents. This poses a significant threat to the well-being of operators and personnel on-site.

This case study explores the collaborative efforts of a West African gold mine and MTS to address operator equipment abuse and its detrimental effects.

The Challenge

A mature West African gold mine was experiencing excessive component damage and premature failures across its fleet. This resulted in disruptions in production schedules and inflated operating costs, heavily impacting their profitability. Upon investigation, a significant cause was identified as operator abuse. Specific issues included:

Improper Handling Techniques: Operators lacked proper training or awareness regarding safe and efficient equipment operation. This resulted in manoeuvres that stressed equipment components beyond their capacities.

Lack of Awareness of Consequences: Operators did not fully understand the long-term implications of their actions. Some were unaware of the impact of abusive behaviour on equipment health, production schedules, and safety.

Normalization of Deviance: These poor practices had become the cultural norm. This wasn’t just a lack of training, it was a case of ingrained bad habits being passed down and accepted as the standard way to work.

The site engaged MTS to help improve operator performance & reduce equipment abuse.

The Solution

Implementing a Multi-Pronged Approach:

MTS adopted a multi-pronged approach to address the identified challenge. The initial step involved collaborating with operators to understand their working habits and identify common abusive behaviours that resulted in equipment damage. This understanding allowed MTS to tailor solutions effectively.

Knowledge Sharing and Training:

To equip operators with the necessary knowledge and skills, MTS partnered with the mine’s training department. This collaboration resulted in the creation of clear and concise operational guides outlining proper equipment handling techniques. The content of these guides was informed by the system health events, focusing on correcting the most frequent and damaging abusive practices. To maximize adoption, the program also leveraged the mine’s best operators to help refine the techniques, which was critical for building trust and operational credibility. These guides focused on:

Safe Equipment Operation: Clear instructions on how to operate equipment within its designated parameters, minimising wear and tear.

Preventative Maintenance Practices: Educating operators on basic maintenance tasks they could perform to identify and address minor issues before they escalate into major breakdowns.

Understanding Equipment Limitations: Emphasis on the importance of adhering to load limits and avoiding manoeuvres that could exceed the equipment’s design capacity.

Data-Driven Performance Monitoring:

Transparency and accountability are crucial for successful performance improvement. To achieve this, MTS implemented a data-driven approach:

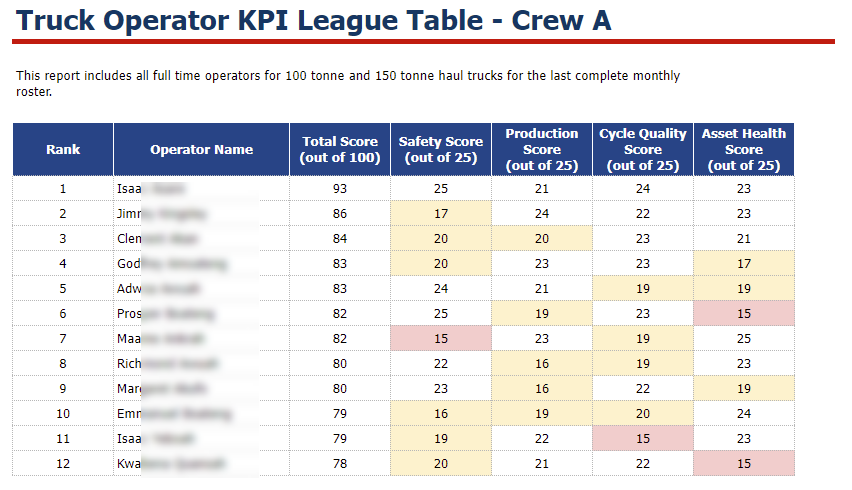

Scorecards: These visualised key performance indicators (KPIs) related to operator behaviour, equipment health and productivity. A balanced scorecard is important in ensuring that all focus is not placed into one category, consequently harming another. These were placed in crew rooms to foster operator gamification of key safety, production and asset health metrics. This included an emphasis on:

Safety: Improved safety scores reflect a reduction in risky manoeuvres associated with operator abuse.

Cycle Quality: This metric encompasses factors like loading efficiency and travel times. Improved cycle quality indicates more efficient equipment operation.

Asset Health: Scores here directly reflect the proper use of the equipment to its designed limits. High scores reflected operators who were not pushing equipment to operate outside of their designed specifications.

Productivity: Metrics tracked production aspects to ensure that compliance in all other areas is not impacting the primary goal.

Support Dashboards: Real-time data dashboards were built and implemented to provide immediate feedback on equipment usage and identify areas requiring attention. Some key features included total abuse events by category, crew and operator with functionality to trend this data over time for performance tracking.

Fostering Teamwork and Collaboration:

MTS recognised the importance of a collaborative approach. They facilitated communication and teamwork between various departments within the mine, including:

Supervisors: Equipped with insights from the scorecards and dashboards, supervisors could provide targeted coaching and guidance to operators.

Operators: Active participation in the program and open communication with supervisors fostered a sense of ownership and accountability for achieving safe and efficient equipment operation.

Maintenance Personnel: Collaboration between operators and maintenance crews allowed for early identification of potential issues and facilitated preventative maintenance practices.

The Results

The collaborative efforts yielded positive results. Observed damage to equipment components saw a significant reduction. Notably, there was a 37% decrease in frame cracks, a critical component prone to damage due to operator abuse. This signifies a direct correlation between improved handling techniques and reduced wear and tear.

Another positive was a substantial 56% reduction in alarms triggered by improper equipment operation. This suggests a significant shift towards more careful handling practices by operators. Furthermore, a clear downward trend in abusive events was observed over a 9-month period, showcasing the effectiveness of the implemented strategies.

Summary

This successful collaboration project provides a valuable case study for the mining industry. It demonstrates the effectiveness of a multi-pronged approach that combines knowledge sharing, data-driven monitoring, and collaborative teamwork in mitigating the detrimental effects of operator abuse. By implementing these strategies, mining companies can achieve significant improvements in operational efficiency, cost-effectiveness, and overall equipment health, ultimately leading to a safer and more productive work environment.

Why Choose MTS for your Mining Technology Needs?

At MTS, we bridge the gap between mining technology, people, and IT. Our experienced team of mining technologists is dedicated to empowering mines to enhance productivity, minimise waste, and optimise costs through the seamless integration of technology.